160 eyeliner pencils in one minute. ATN timing belts

in the service of beauty

ATN

timing belts from the MULCO EWIV Europe Group of Companies are not

only one of the latest innovations of drive technology, they are

also in the direct service of beauty. Every woman will know how to

use an eye liner in order to bring a certain depth and expression to

the eyes, but very few know just how fragile and difficult it is to

move the core of this metal or cedar wood pencil with bare hands. It

is therefore

even more

astonishing that a packing machine can handle the leads of the eye

liner pencil so gently that even soft female hands can't improve on

this. ATN

timing belts from the MULCO EWIV Europe Group of Companies are not

only one of the latest innovations of drive technology, they are

also in the direct service of beauty. Every woman will know how to

use an eye liner in order to bring a certain depth and expression to

the eyes, but very few know just how fragile and difficult it is to

move the core of this metal or cedar wood pencil with bare hands. It

is therefore

even more

astonishing that a packing machine can handle the leads of the eye

liner pencil so gently that even soft female hands can't improve on

this.

This process, developed into a real marvel of technology by

Hans-Joachim Lortz, owner of the LogicPak in Hessian Dieburg, is

called "sleeving" within the packing industry. "Sleeves“ are

hose-type wrappers made of shrink-down plastic which protect fragile

products such as the eye liner leads mentioned above as well as, for

instance, plastic bottles with baby food or other fillings which

should not be

manipulated in any way by the trade. The tightly fitting,

shrunk-down "sleeve“ can only be destroyed by force.

As

developer and supplier of these sleeve machines, LogicPak is one of

the first ports of call whenever

difficult products

or those requiring protection have to be sealed partially or

completely in a shrink-down film. The introduction of the innovative

ATN timing belts in place of the previous chain drives and conveyors

has turned these sleeve machines from Dieburg into an even more

desirable product. As

developer and supplier of these sleeve machines, LogicPak is one of

the first ports of call whenever

difficult products

or those requiring protection have to be sealed partially or

completely in a shrink-down film. The introduction of the innovative

ATN timing belts in place of the previous chain drives and conveyors

has turned these sleeve machines from Dieburg into an even more

desirable product.

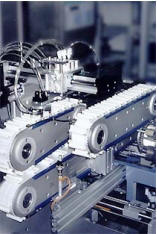

Hardly has it been introduced on the market than the ATN timing belt

is giving

manufacturers of drive chains sleepless nights. Developed by BRECO-Antriebstechnik

Breher GmbH & CO, one of the most innovative producers in the field

of timing belt technology and a member of the MULCO

Europe EWIV Group of

Companies, the ATN impressively demonstrates the possibilities

further development of the tried and test polyurethane timing belt

can offer.

In co-operation with the MULCO-Europe EWIV member Hilger und Kern

GmbH, Mannheim,

LogicPak looked for

and found a way to optimise the transportation, insertion and

subsequent shrinking of the protective film in a hot air tunnel of

tiny and fragile products, some of which are almost impossible to

process by hand, from the cosmetics and writing implements industry.

Up to 160 of the extremely fragile eye liner leads, measuring just 4

mm in diameter, are picked up per minute by the

sleeve machine as

gently as if wearing glacé gloves and transported to the sleeving

station with flighted ATN 12.7 inch pitch timing belts. Not a single

piece is broken, something just not possible at this speed if

handled manually.

Two

mandrels, one to stop the product and one to carry the sleeve, then

envelop the product as if by magic and transport it to the hot air

shrink-down station. Two

mandrels, one to stop the product and one to carry the sleeve, then

envelop the product as if by magic and transport it to the hot air

shrink-down station.

A brilliant idea - but it was the fast-growing market which promoted

and demanded the rapid development of the design. New fields of

application and products to be sleeved are opening up all the time.

"Our technology makes it possible, by means of special retainers, to

process products with an asymmetric and insecure surface“, states

Hans-Joachim Lortz, showing sleeved ballpoint pen housings, cosmetic

pencils or pharmaceutical products as small as a thumbnail.

However, the chain drive of the machine did not meet the high

demands of Hans-Joachim Lortz. Although no high torque and forces

require transferring, the machine, controlled via 11 axes, should

require even less maintenance and be even easier to operate, and

should in particular be easier to set up for a change of format.

This optimal solution from Hans-Joachim Lortz is offered by the ATN

timing belt. Compared to other solutions such as welded flights or

chains, for instance, the present application, combined with a

two-part sliding flight system, provides exactly the right

flexibility required by customers. The customer now has lower costs,

because the personnel required for a format change only need to be

instructed in the specific tasks, which is a lot cheaper than

general training.

Here Hans-Joachim Lortz has a quite simple philosophy: “We have

developed a module. Every operation should be foolproof in its

execution. A change of format means red flights in, blue flights out

or the other way round“. No time-consuming removal of chains and

flights, making conversion of the machine for other formats and

products a simple task. The operator simply slides the

milled-to-size retainers on to the flights designed for the

measurements of the product to be sleeved.

The ATN timing belt pushed by the drive starts gently, does not

require any greasing and maintenance and has a long service life.

There is no question that particularly product sensible branches are

happy at not having to grease the chain conveyor, particularly as

the lubricant presents a considerable danger of contamination for

the products to be sleeved.

The LogiPak design of the ATN timing belt is extremely flexible in

its application and offers critical advantages such as:

-

use of various flight materials

-

variable flight pitch

-

high flight position accuracy in relation to the timing belt

-

designers can react a lot faster to changing field conditions or

products because there is no need to use a new PU timing belt,

with the correspondingly great expense for tools and moulds

-

ATN lowers development costs in relation to time. Tests lead to

sophisticated designs much faster.

Based on the proven material composition of the PU timing belts and

a good stock of standard dimensioned ATN 10, ATN 12.7 and ATN 20

belts in four widths, the application possibilities and flight

shapes are only restricted by the creativity of the designers - but,

as we know, this has no limit! |