| AeroGo air caster equipment uses a variety of

Aero-Casters® to literally float heavy loads on a virtually

frictionless film of air. Air casters provide a clean, quiet and

safe alternative to moving heavy loads. |

|

|

Reduced friction and omni-directional movement allow the operator to

precisely place and align the load in a limited work space. The low

profile of the air caster Load Module requires less than 3-inch

(76mm) clearance. Air casters will not damage floors and expensive

reinforcement is usually not necessary.

Because we use only basic pneumatic components such as air

regulators and hoses, our products are not only reliable, but will

operate in most environments.

|

| The Aero-Caster Principle |

|

|

|

HOW AEROGO AIR CASTERS WORK: |

|

|

Step 1

Prior to inflation, the load is solidly supported on landing pads.

These pads protect the air caster torus bag from being crushed when

the load is at rest.

|

|

Step 2

When standard shop air is applied to the air caster, the torus bag

inflates, creating a seal against the floor surface and raising the

load. |

Step 3

When the pressure within the chamber is sufficient to offset the

load's weight, air slowly and evenly escapes between the flexible

torus bag and the floor. The load is literally floated on a thin,

nearly frictionless cushion of air, .003 to .005 inches (.08 to

.13mm) thick. |

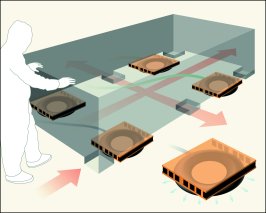

LOAD MODULE SYSTEMS

|

|

|

Load Module Systems move loads of varying sizes,

shapes or weights. Weight capacities 1 to 360 tons utilizing 4 or 6

module configurations. Need to move equipment in a cleanroom

environment? Ask about our anodized or powder coated models.

Load Module Systems Tips:

- Basic Even Loading - Know your load weight and how it's

distributed to move safely. Contact us prior to your next move

if you have any questions.

- Load Modules provide optimal load balance when arranged

under the load in a triangle, square or 6-way pattern.

- Familiarize yourself with your control console it will

facilitate your move over temporary overlays, floor joints or

cracks.

|

|

Click on the link below for further information

such as video demonstrations and literature:

|